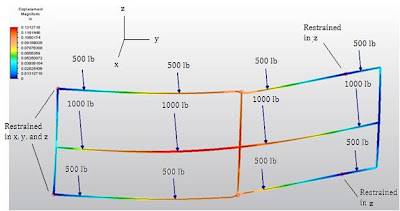

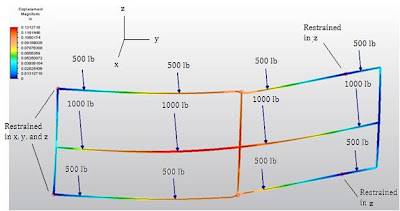

The team is continuing to make progress! Our material of choice is Aluminum 6061-T6, with the primary structure of the pallet being made using a standard 6" x 6" channel cross section. Calculations have begun, also, now that we have received the full set of specifications from NASA. The figures below show the results the team has obtained so far using ALGOR.

|

| Loadings and Boundary Conditions for an Initial Model in ALGOR | | | | |

|

|

| Part 1 of Bending Stress Results |

| |

| Part 2 of Bending Stress Results |

Because the pallet must be assembled inside the Orion module, we have some additional constraints. We decided to follow Lockheed Martin's lead on the original design by dividing the pallet into three parts. However, we need to make sure that the three sections are not too heavy for the team to lift. We also need to join the three sections once inside the module. Currently we are looking at the use of sleeves and bolts to join the sections, but welding remains an option.

Another major focus at this time is the attachment points where the pallet is supported by the struts. We are going to be looking at sizing the fasteners so that they can handle the load -- we will have 6000 lbs supported at four points (only four of the struts carry a vertical component).